How to Read an Outside Micrometer

A micrometer generally provides greater precision than a caliper, but is limited

to a smaller range of lengths. For example, it would take a six-piece set of

micrometers to cover the range of a 6” caliper.

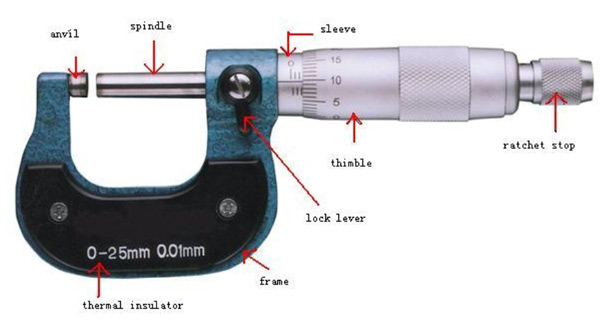

Parts of an Outside Micrometer

Proper Use and Care for a Micrometer

Be sure to unlock the locking lever before attempting to rotate the thimble.

Clean the measuring faces with a clean cloth before and after measurements.

It is also a good practice to occasionally clean the spindle to keep any contaminants from being drawn into the sleeve. Use the grip on the thimble when requiring a large amount of travel but as you come close to closing in on the object to be measured use the ratchet stop so as to not over tighten the thimble and give an erroneous reading. Never leave a micrometer exposed in the hot sun and then attempt a measurement. This would also lend to an erroneous reading. When a micrometer is at its minimum reading the horizontal line on the sleeve should line up with the ‘0’ on the thimble. If that is not the case it will be necessary to calibrate the micrometer by rotating the sleeve. Each micrometer comes with a half moon adjusting wrench for this purpose. To make the adjustment simply puzzle the wrench to the side of the spindle and insert the small tip into the leverage hole. It will not require much effort to turn the spindle however there is sufficient resistance in the spindle so that it will never move on its own. Larger micrometers are supplied with standards to check for correct calibration. When checking, be sure to hold the standard squarely between the anvil and spindle. To help with this try rotating the standard slightly with your fingers while gently turning the thimble as you close in on the standard.

Parts of an Outside Micrometer

Proper Use and Care for a Micrometer

Be sure to unlock the locking lever before attempting to rotate the thimble.

Clean the measuring faces with a clean cloth before and after measurements.

It is also a good practice to occasionally clean the spindle to keep any contaminants from being drawn into the sleeve. Use the grip on the thimble when requiring a large amount of travel but as you come close to closing in on the object to be measured use the ratchet stop so as to not over tighten the thimble and give an erroneous reading. Never leave a micrometer exposed in the hot sun and then attempt a measurement. This would also lend to an erroneous reading. When a micrometer is at its minimum reading the horizontal line on the sleeve should line up with the ‘0’ on the thimble. If that is not the case it will be necessary to calibrate the micrometer by rotating the sleeve. Each micrometer comes with a half moon adjusting wrench for this purpose. To make the adjustment simply puzzle the wrench to the side of the spindle and insert the small tip into the leverage hole. It will not require much effort to turn the spindle however there is sufficient resistance in the spindle so that it will never move on its own. Larger micrometers are supplied with standards to check for correct calibration. When checking, be sure to hold the standard squarely between the anvil and spindle. To help with this try rotating the standard slightly with your fingers while gently turning the thimble as you close in on the standard.

Click to go to

1. Reading a .001” scale

2. Reading a .0001” scale

3. Reading a .01mm scale

4. Reading a .001mm scale

First of all, the basics:

The pitch of the screw thread on a standard spindle is 40 threads per inch. One revolution of the thimble advances the spindle face toward or away from the anvil face precisely 1/40" or 0.025" equaling the distance between two graduations on the sleeve. The reading line on the sleeve is divided into 40 equal parts by vertical lines that correspond to the number of threads on the spindle. Therefore, each vertical line designates 1/40" or 0.025". Every fourth line, which is longer than the others, designates 0.100" and is numbered. The beveled edge of the thimble is divided into 25 equal parts with each line representing 0.001" and every line may or may not be numbered however every fifth line is numbered consecutively. To read the micrometer in thousandths, multiply the number of vertical divisions visible on the sleeve by 0.025", and to this add the number of thousandths indicated by the line on the thimble which best coincides with the central long line on the sleeve.

Now some examples:

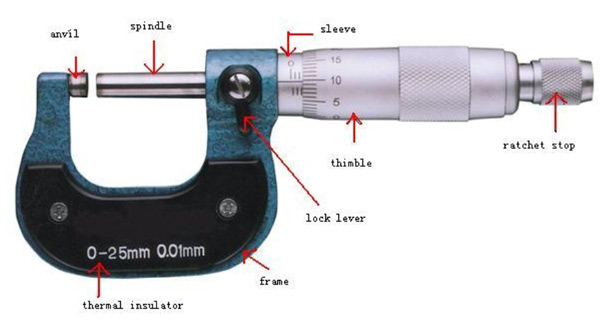

How to read a micrometer graduated in 0.001"

Micrometer thimble showing 0.276 inch

In the picture above, the thimble is positioned to where it is setting between the 2nd and 3rd numbered graduation thus 2 x 0.100” = 0.200”. Past that there are three additional sub-divisions, which is 3 x .025” = 0.075”. Lastly the graduation 1 on the thimble is the closest to the central long line on the sleeve therefore 1 x 0.001” = 0.001”. The reading thus would be 0.200” + 0.075” + 0.001”, totaling to 0.276".

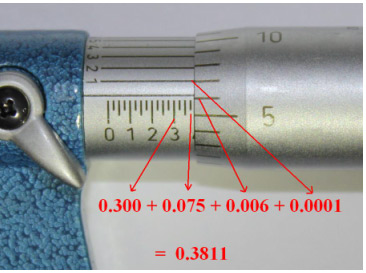

How to Read an Outside Micrometer Graduated in 0.0001" (using the extra vernier scale).

Many micrometers include a vernier scale on the sleeve in addition to the regular graduations. This allows measurements within 0.001 millimeters to be made on metric micrometers, or 0.0001 inches on inch-system micrometers.

The additional digit of these micrometers is obtained by finding the line on the sleeve that best coincides with the line on the thimble. The number of this coinciding vernier line represents the additional digit.

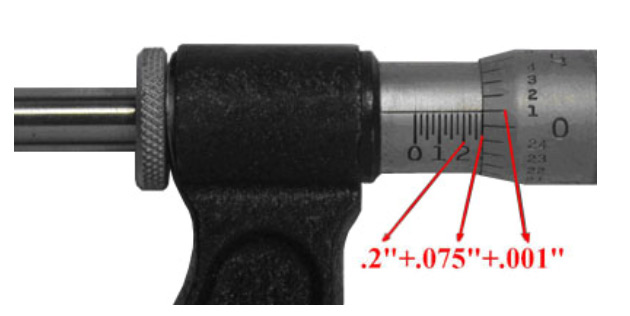

This next example uses a 1” to 2” micrometer (shown with the 1” standard).

The horizontal scale on the sleeve is marked with graduations every .025 (25 thousandths). Every 4th graduation (starting after ‘0’) is numbered consecutively. These numbers represents 0.100 (4 x .025 = 0.100) which is read as 100 thousandths.

The vertical scale graduations on the thimble represent .001 (1 thousandths). Every 5th graduation is numbered for clarity.

The vertical scale graduations on the sleeve represent .0001 (tenth of a thousandths). This is the vernier scale.

Micrometer reading 1.1551 inches

The reading for this example is determined by adding five separate figures.

And these are:

· Length of the standard - 1.0000

· The numbered graduation on the sleeve – ‘1’ or 0.1000

· Two additional graduations on the sleeve – 2nd line past the ‘1’ which is 2 x .025 = .050 (50 thousandths).

· The number of thousandths on the vertical scale of the thimble - between 5 and 6 therefore .005

· The best match up of the two vertical scales which is 1 therefore .0001

Total of all five figures:

1.0000

0.1000

0.0500

0.0050

0.0001

is

1.1551 which is simply read as “1.1551 inches” or could be read as “one and one thousand five hundred fifty one ten-thousandths of inches”.

Another example in inches using a 0” to 1” micrometer:

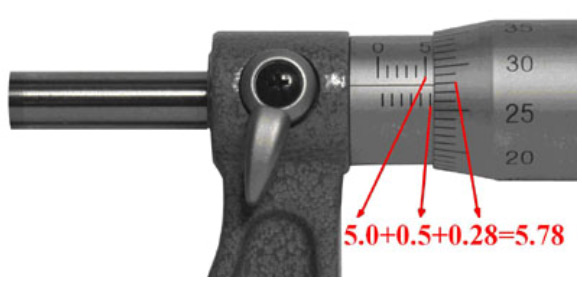

How to read a micrometer graduated in 0.01mm

The pitch of the screw thread on a metric spindle is one-half millimeter (0.5mm). One revolution of the thimble advances the spindle face toward or away from the anvil face precisely 0.5mm. The reading line on the sleeve is graduated above the central long line in millimeters (1.0mm) with every fifth millimeter being numbered. Each millimeter is also divided in half (0.5mm) below the central long line. The beveled edge of the thimble is divided into fifty equal parts, with each line representing 0.01mm and every fifth line being numbered from 0-50. Thus, the number of millimeter and half-millimeter divisions visible on the sleeve plus the number of hundredths of a millimeter indicated by the thimble graduation, which coincides with the central long line on the sleeve, give the reading.

Micrometer thimble reading 5.78mm

In the picture above, the thimble is positioned to where the edge of the thimble bevel is positioned between the 5th and 6th graduation on the upper side of the scale thus 5.0millimeter. It is also past the next graduation on the lower side of the scale thus an additional 0.5mm. Finally graduation 28 (.28) on the thimble coincides with the central long line on the sleeve. The reading then would be 5.00 + 0.5 + 0.28 = 5.78 mm.

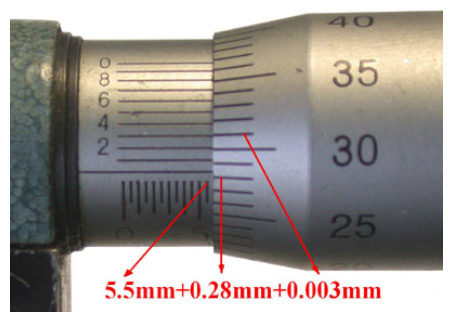

How to read a micrometer graduated in 0.001mm

In the above picture this micrometer has the additional vernier scale on the sleeve. It is reading about the same as the previous example however a more accurate reading can be obtained with this vernier scale. The #31 graduation on the thimble lines up best with the .003 graduation mark on the sleeve. Thus the reading would be 5.00 + 0.5 + 0.28 + .003 = 5.783mm.

For accurate readings on all precision measurements it is important to hold the work piece squarely with the measuring tool. Consider purchasing a micrometer stand that can serve as a ‘third hand’. A stand can greatly improve the accuracy of a measurement and actually speed up the process especially when measuring parts repetitiously.

Most open-end wrenches need a minimum of a 60º swing angle

to ratchet. Our wrench requires only half of that at 30º of swing because of the

patented design. Coupled with small head size and a design with increasing

interactive grip---it sets a high standard in the open-end ratchet system

Most open-end wrenches need a minimum of a 60º swing angle

to ratchet. Our wrench requires only half of that at 30º of swing because of the

patented design. Coupled with small head size and a design with increasing

interactive grip---it sets a high standard in the open-end ratchet system